Disinfectant Evaluation

Disinfectant Evaluation

Contents

• Methods for disinfectant evaluation

• Bacteriostatic evaluation tests

– Serial dilution in liquid media

– Serial dilution in solid media

– Cup plate

– Ditch plate

– Gradient plate

• Evaluation of aerial disinfectants

Intended Learning objectives

At the end of this lecture, student will be able to

• Classify different methods for disinfectant evaluation

• Differentiate between bactericidal and bacteriostatic evaluation tests

• Explain the various bacteriostatic evaluation tests for disinfectants

• Explain the significance of capacity tests

• Explain the method for evaluation of solid disinfectants

Introduction

• Disinfectant evaluation – Tests used to assess bacteriostatic and bactericidal activity of disinfectants

• Bacteriostatic activity – ability of an disinfectant to stop the growth of microorganisms

• Bactericidal activity – ability to kill the organism

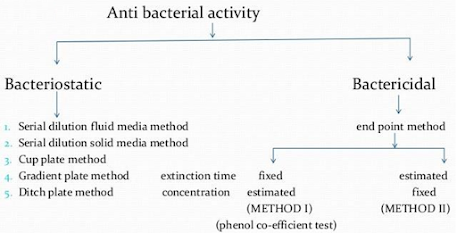

Tests for disinfectant activity

| SUBSTANCE TESTED | BACTERIOSTATIC TESTS | BACTERICIDAL TESTS |

| Liquid disinfectants | Serial dilution in fluid media | End-point or extinction time methods |

| | Serial dilution in solid media | Counting methods |

| | Cup-plate, fish-spine bead and filter paper methods | Turbidometric assessment |

| | Gradient-plate method | ‘In use’ and other tests |

| | Ditch-plate technique | Additional in vivo tests can be applied |

| Semi-solid antibacterial formulations, e.g. creams, ointments, pastes and gels | Cup-plate methods | Modified end-point or extinction time methods |

|

| The ditch-plate technique | Additional in vivo tests can be applied (e.g. skin tests) |

| Solid disinfectants, disinfectant powders | Inhibition on seeded agar | Modified end-point or extinction time methods |

| Aerial disinfectants | Use of slit-sampler in test chamber | |

Tests applied to liquid disinfectants Bacteriostatic activity

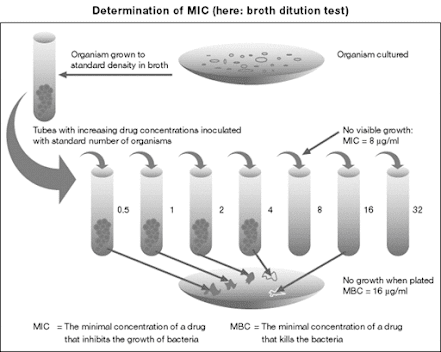

Serial dilution in fluid media

• Minimum Inhibitory Concentration (MIC) – the minimum concentration preventing detectable growth is taken as the measurement of bacteriostatic activity

• MIC varies with inoculum size, medium used and incubation conditions.

Serial dilution in solid media

1. A suitable volume of double strength nutrient agar

2. Diluted with an equal volume of bacteriostatic solution

3. Poured into sterile petri plate

4. Surface is dried by incubating at 37⁰C for 1 h

5. Drops of the test organism are placed on the dried surface

6. Incubated for 2 to 3 days

7. A separate petri dish is used for each concentration of bacteriostatic

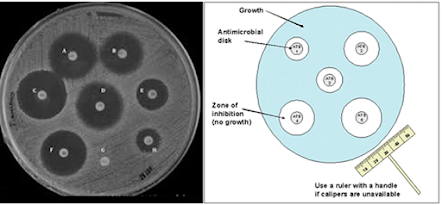

• Cup-plate, fish-spine and filter paper methods

• Agar medium is melted, cooled suitably and inoculated with the test organism

• Poured into a sterile petri dish

• Cup-plate:holes about 8 mm in diameter are cut in the agar with the help of a sterile cork borer

• Antimicrobial agent is placed in the holes

• Fish-spine bead, filter paper and cylinder method

• In all the cases, zones of inhibition may be observed

• The diameter of zones of inhibition gives rough indication of

– The relative activities of different antimicrobial substances against the test organism

– The effect of different concentrations of antimicrobial substance

The gradient - plate method

• Agar is streaked in the same line as the slope of the agar (along the concentration gradient) and reincubated.

• Approximate MIC is obtained from the equation

MIC=CX(x/y)mg/ml

C= concentration, in mg/ml, in total volume (i.e, volume of wedges A and B)

X=Length of growth, in cm

Y= total length of possible growth, in cm

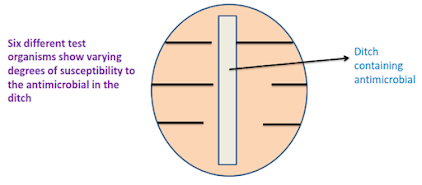

The ditch-plate technique

Carrier test

• A carrier such as a silk or catgut thread is contaminated by submersion in a liquid culture of the test organism

• The carrier is then dried and brought in contact with the disinfectant for a given exposure time

• Cultured in a nutrient broth

• No growth indicates activity of the disinfectant tested whereas growth indicates a failing.

• By multiplying the test concentrations of the disinfectant and the contact times, a potentially active concentration-time relationships of the disinfectant is obtained.

Limitations

a) The number of bacteria dried on a carrier is hard to standardize

b) The survival of the bacteria on the carrier during drying is not constant.

The AOAC Use – Dilution Test

• The AOAC Use-dilution test

• AOAC (American Association of Official Analytical Chemists)

• A carrier-based test

• Organisms: Salmonella cholerasuis, S. aureus and P. aeruginosa

• Carriers (stainless steel cylinders) are meticulously cleaned, sterilized, cooled and inoculated with a test organism by immersing in one of the culture suspensions

• The cylinders are drained on filter paper, dried at 37°C for 40 minutes, exposed to the use-dilution of the disinfectant for 10 minutes.

• After transfer from the disinfectant, the treated test surfaces are incubated in the neutralizing growth medium for 48 hours

• The number of tubes showing growth of the target microorganism is recorded.

• To “PASS" a 60 carrier test, at least 59 of the 60 surfaces tested must demonstrate complete disinfection (no detectable growth of the target microorganism in the test tubes containing neutralizing growth medium)

• To "PASS" a 10 carrier test, complete disinfection must take place on all test surfaces.

Suspension tests

• A sample of the bacterial culture is suspended into the disinfectant solution

• After exposure it is verified by subculture whether this inoculum is killed or not.

• Suspension tests are preferred to carrier tests as the bacteria are uniformly exposed to the disinfectant.

Types

A. Qualitative suspension tests:

• Loopful of bacterial suspension brought into contact with the disinfectant

• A loopful of this mixture cultured for surviving organisms.

• Results expressed as ‘growth’ or ‘no growth’.

B. Quantitative suspension tests.

• The number of surviving organisms (B) is counted and compared to the original inoculum size (A).

Microbicidal effect (ME) = Log (A) - Log (B)

• ME = 1 → killing of 90% of the initial number

• ME = 2 → 99% killed.

• A generally accepted requirement is:

• ME ≥ 5 →99.999% of the germs are killed.

Capacity test

• The ability to retain activity in the presence of an increasing load is the capacity of the disinfectant.

• In a capacity test, the disinfectant is challenged repeatedly by successive additions of bacterial suspension until its capacity to kill has been exhausted.

• Capacity tests simulate the practical situations of housekeeping and instrument disinfection.

• Best known capacity test is the Kelsey-Sykes test (Kelsey and Sykes, 1969).

Kelsy-Sykes ‘In-use’ tests

• A triple challenge test, designed to determine concentrations of disinfectant that will be effective in clean and dirty conditions.

• Organisms: 4 organisms (S. aureus, E.coli, Psedomonas aeruginosa and Proteus vulgaris)

• Three successive loads of bacteria (additions) Transfer 1ml at 0, 10, and 20 mins

• Temp: 20⁰C

• Calibrated pipette for subculture rather than loop

• Clean and dirty conditions

• Assessment (kill or not)

| Time from start (min) | Procedure |

| 0 | Inoculate 3ml of the disinfectant dilution with 1ml of bacterial suspension in broth, yeast or serum and shake gently (this gives a bactericide/bacteria reaction mixture) |

| 8 | Remove sample from above reaction mixture with a 50 dropper pipette. Transfer 1 drop to each of 5 tubes of liquid recovery media, or 5 drops to the surface of a nutrient agar plate |

| 10 | To bactericide or bacteria reaction mixture, prepared at start (time 0), add a second 1 ml of bacterial suspension |

• Sets that contain two or more negative cultures are recorded as a negative result.

• The disinfectant passes at the dilution tested if negative results are obtained after the first and second challenges.

• The third challenge is not included in the pass/fail criterion but positive cultures serve as inbuilt controls.

• If there are no positive cultures after the third challenge, a lower concentration of the disinfectant may be tested.

Tests on aerial disinfectants

• A closed room of approximately cubic dimensions and 1000cu ft capacity is used

• Fans incorporated to ensure uniform mixing of bacteria and bactericide

• Staphylococcus albus (non clumping strain) is used as the test organism

• Dispersion of organism is done using collision inhaler

• Air samples are taken using a slit sampler at suitable intervals

• The room should be initially free from extraneous microorganisms

• Temperature and humidity of air controlled

• Cyclopentanol-1-carboxylic acid is chosen as the reference standard for air disinfection

Tests applied on solid disinfectants

• Disinfectant powder is mixed with an inert substance such as talc or kieselguhr to form a disinfectant powder

• Powder is dusted onto inoculated plates

• Inert diluent is used as the control

• Alternatively Rideal Walker coefficient can also be used

• A weighed sample is shaken with distilled water at 18⁰C for 3 min

• The suspension is used for the Rideal-walker test

Summary

• Bacteriostatic tests – evaluate the property of stopping the growth of microorganisms

• Bactericidal tests – evaluate the killing property

• Bactericidal tests

– Serial dilution in solid media

– Serial dilution in liquid media

– Cup plate

– Ditch plate

– Gradient plate

• Aerial disinfectants evaluated by using a slit sampler and Staph albus as test organism

• Solid disinfectants – sprayed over the surface of a inoculated plate

For PDF Notes Click on Download Button

0 Comments: